Use control or command click for new tab or window.

Prerequisites: Mechanics of materials, such as the following. MSE 441 co-requisite or EMA 303 prerequisite or equivalent or consent of instructor.

Instructor: Rod Lakes, Professor. Office: 541 ERB.

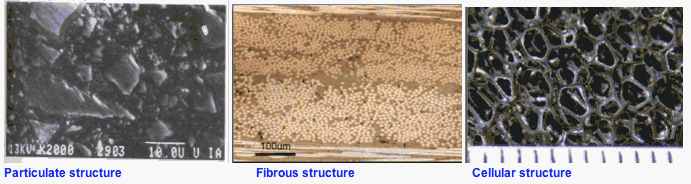

Description: Principles of the mechanics of solid multiphase systems. Role of heterogeneity and anisotropy in determining physical properties including elastic, dielectric and piezoelectric properties. Applications in lightweight structures, ultra-strong materials, materials for protection of the body, and materials for the replacement of human tissues. Materials with fibrous, lamellar, particulate, and cellular structures. Heterogeneous materials of biological origin. Metamaterials and biomimetic and bio-inspired materials.

Goals: To prepare seniors and graduate students to understand physical properties, particularly mechanical properties of heterogeneous and multiphase materials; and the cultivation of physical insight in that regard.

Textbook: R. S. Lakes, Composites and Metamaterials, World Scientific, (2020). ISBN 978 981 121 636 7

Book outline Book publisher link

Grading: Grading is typically based on homework (15%), projects (20%) and quizzes (65%). There are typically two one hour quizzes and a two hour final quiz.

The scale is 90-100% - A, 85-89 AB, etc. Homework is typically due in one week. Project due dates will be announced. Homework grades will be reduced by 5% per working day (Monday-Friday) of additional delay. All assignments must be submitted in paper form, not electronic, during in-person instruction. Short assignments may be hand written. Project reports may be single space, double side: your choice.

Homework is due one week after it is assigned (in class) unless otherwise stated. Project reports are due two weeks after they are assigned unless otherwise stated.

We have have had hands-on projects involving making and testing of materials. In 2020 and 2022 we had such projects as well.

Electronics: Bring a calculator to quizzes. Use phones outside class only to avoid distraction. It is OK to take notes on a tablet or laptop. Do not take photographs of human beings without permission. If you wish a scan of class notes, please ask and one will be provided. Keep in mind writing it down enhances comprehension. If you feel that you need to use a device for substantive reasons, please discuss prior to class.

Course Outline

I: Introduction. Material heterogeneity. Survey of laminated, fibrous, particulate, cellular and porous, platelet structures. Single crystal properties and polycrystal properties. Heterogeneity of biological materials and designed heterogeneity. Strength of fibers. Constituent materials. Griffith's experiments, stress concentrations. Concept of equivalent homogeneity. Micro and nanotructures.

II: Structure, properties and bounds. Unidirectional fibrous media. Bounds on physical properties: Voigt and Reuss bounds; Hashin-Shtrikman bounds. Realization of extremal properties. Prediction of stiffness and strength for different directions.

III: Symmetry and anisotropy. Symmetry and physical properties. Crystal symmetry classes. Isotropy, cubic, hexagonal, orthorhombic, monoclinic, triclinic symmetry. Application of anisotropic elasticity to composites. Generalized Hooke's law of elasticity. Modulus and compliance matrices. Anisotropy and dielectric and piezoelectric properties. Thermal expansion. Experimental methods.

IV: Coupled fields; smart materials Piezoelectric properties, symmetry, causes. Elastic moduli of piezoelectric solids. Piezoelectric materials. Pyroelectric and ferroelectric materials. Thermal expansion. Fluid-solid composites.

V: Particles, fibers, platelets. Structure. Particulate materials. Dental composites, metal matrix composites, asphalt. Toughened polymers via compliant inclusions. Stiffness vs. volume fraction. Self healing polymers. Attainment of the Hashin-Shtrikman bounds. Unidirectional fibrous materials; stiffness, strength, thermal expansion. Fibrous solids with short-fibers. Nano-tubes as fibers. Platelet reinforcement. Shear lag model. Laminates. Polycrystalline aggregates. Piezoelectric composites. Metal matrix composites. In situ composites; eutectic structure.

VI: Cellular solids and lattices. Structure property relations of cellular solids. Lightweight cellular solids. Foams, structural honeycombs, sandwich structures. Polymer lattice structures. Dense foams; syntactic foams. Poisson's ratio of composites and foams. Hierarchical honeycomb, foam and lattices. Design of hierarchical solids. Applications.

VII: Biological material structural hierarchy. Hierarchical structure: structure within structure. Bone, wood, tendon and other materials of biological origin. Fibrous aspects of bone structure. Tendon and ligament as fibrous biological materials. Biological cellular solids. Cellular architecture of bone, wood, bamboo. Enhancement of physical properties.

VIII: Size of heterogeneity. Fracture mechanics, stress concentrations, free-edge effects. Role of microstructure size. Gradient effects. Generalized continuum models; Cosserat elasticity; size effects. Toughness: empirical criteria; causal mechanisms.

IX: Viscoelastic composites. Creep, relaxation, vibration damping. Bounds on stiffness-loss map. Role of the shape of the heterogeneity. Experimental methods. Applications.

References and resources

L. J. Gibson, and M. F. Ashby, Cellular Solids, Cambridge, (1999).

M. F. Ashby and D. R. H. Jones, Engineering Materials, 2nd ed. Butterworth, (1998).

J. F. Nye, Physical Properties of Crystals, Oxford, (1976).

B. D. Agarwal and L. J. Broutman, Analysis and Performance of Fiber Composites, J. Wiley, 2nd ed. (1990).

Graphs

For those who use KaleidaGraph to draw graphs, this software can import data from text files or from Excel. The rationale is to achieve better quality of graphs. Here are links to a tutorial

Expected outcome

Develop clear understanding of the role of material heterogeneity; develop physical insight; develop ability to design systems with heterogeneous materials.

Gain a basic understanding of heterogeneous materials Develop skill in solving problems to predict response of such materials Learn how to interpret material properties Learn about classical and contemporary heterogeneous materials Practice designing, 3D printing, testing and interpreting results for rib and plate lattice materials. Undergraduate students: learn about applications of heterogeneous materials in industry. Graduate students: learn about current developments in the field and will cultivate critical thinking on novel materials.

To refrain from adding any further burden of dystopia in the 2020 and 2022 offerings, we did not expect any student to install or use invasive software for quizzes or any other purpose. We did not expect to access your web cam and we did not look at you through it. We have never monitored your email or other communications. We do not force intrusive software on your phone and do not track you through your phone. We do not monitor use of apps on your phone. We do not force surveys via robotic software.

I thank many sincere and enthusiastic students who over the years made this course very rewarding to teach. I also thank Professor Sue Babcock, who as department chair of Materials, provided support and encouragement.

~