Research

Hydrogels for Microfluidic Device and Tissue Engineering Applications

|

Polymeric hydrogels are a class of shape memory materials that undergo a swelling transformation. A large reversible volume change can be induced in these materials by changes in environmental conditions such as pH. Applications of hydrogels range from sensors, to wound repair, to drug delivery. Our research has focused on developing and adapting experimental mechanics techniques for the mechanical characterization of these materials. These results have been used to produce models of the material behavior of hydrogels. Currently we are investigating the force response of hydrogels. The results will facilitate hydrogel’s use as autonomous actuators in microfluidic devices. |

Hydrogels and Stem Cells

Recent research involves the response of stem cells to a surrounding three-dimensional hydrogel matrix. The objective of this research is to test the influence of hydrogel material properties and mechanical stimulation on the differentiation of stem cells. Hydrogels have been shown to have promise for a range of biomaterials and biomedical device applications, including cell scaffolding, artificial tissues, wound repair, drug delivery, and microfluidic devices. Our work will ultimately impact the development of tissue-engineered constructs for cardiac repair. It has been demonstrated that embryonic stem cells can be placed in the heart and aid in repair, however there are a number of open issues including holding cells in place in the heart and facilitating their survival and development into useful tissue. Hydrogels hold substantial promise for addressing these issues, but proper materials selection and materials design to optimize of the cell-hydrogel interactions is required before a viable treatment option can be developed. Our research aims focus on engineering hydrogel materials with mechanical properties consistent with cardiac tissue, exploring the impact of hydrogel stiffness on differentiation of stem cells, and investigating the influence of applied stress on differentiation of stem cells.

See this link for more information on the Stem Cell and Regenerative Medicine Center: SCRMC |

Biomaterials and Biomechanics

Biomedical devices such as stents and vascular grafts are often coated with various materials to prevent problems such as clotting around the instrument. Typically, the base material provides the mechanical properties desired while the coating provides biocompatibility. An alternative approach is to make the base material biocompatible. Our reach has focused on both surface modification of NiTi shape memory alloys and development of polyurethane based polymers that possess mechanical properties similar to the surrounding biological materials. Matching the mechanical properties, especially the stiffness, of the device to the surrounding structures results in better performance. These research topics have been supported by the Whitaker Foundation and the Coulter Foundation. |

Shape Memory and Superelastic Behavior

|

Shape memory alloys are a unique class of materials that undergo a reversible phase transformation that allow the material to display dramatic stress-induced and temperature-induced deformations which are recoverable. Nickel titanium (NiTi) is one such shape memory alloy used in a range of industries for products such as biomedical devices and aerospace components. The austenite-martensite phase transformation that occurs in shape memory alloys with changes in temperature or the applied stress is responsible for the unique thermomechanical properties of this material. My work has focused on developing a better fundamental understanding of these through investigation of its macroscopic behavior and phase transformation mechanisms at the microscopic level.

The figure shows two transformation

fronts (black bands) separating from a nucleation point in NiTi wire. The material is transforming from a martensite phase to an austenite phase. Austenite is present between the transformation fronts.

|

Nickel titanium (NiTi) is a particular shape memory alloy used in a wide variety of biomedical, aerospace, automotive and other applications. The most

common use of NiTi that people are familiar with is the dental arch wire used in

orthodontic braces. NiTi is also used to make high integrity couplings and

connectors for defense, aerospace, and electronic applications where space

savings and reliability are of key importance. |

See this education link for more background on shape memory alloys: MRSEC

|

Fracture of Shape Memory Alloys

|

Our research has addressed several key questions concerning the fracture behavior of NiTi and CuAlNi with funding from the National Science Foundation through a CAREER Award. NiTi is the shape memory alloy (SMA) most frequently used commercially. However, due to the cost of raw materials and difficulty of processing, applications using NiTi are limited due to cost. Another SMA that has drawn interest is CuAlNi given the low cost of raw materials and ease of processing. However, CuAlNi has not been used due to the tendancy of this alloy to fracture intergranuarlly at a low number of thermal or mechanical cycles. In order to understand the fracture mechanisms of shape memory alloys, experiments on notched polycrystalline and single crystal samples are currently being performed. These experiments will assist in developing experimentally based models that delineate the mechanisms influencing fracture in NiTi and Cu-based shape memory alloys. |

Nanostructured Shape Memory Alloys

|

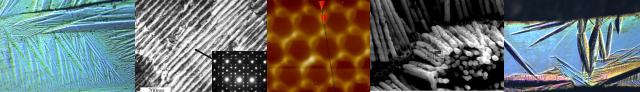

Nanoscale materials have attracted strong interest because of the novel material properties that become possible when surface effects and grain boundary behavior play a larger role in the overall mechanical behavior of the material. Shape memory alloys also continue to be explored for more dramatic superelastic behavior. It has been shown that refinement to the microscale is correlated with enhancement of the properties in copper-based, iron-based alloys, and nickel-titanium shape memory alloys. Taking this a step further, Prof. Crone and her collaborators have been exploring the properties that result from combining the effects of nanostructures and shape memory. At the onset of this research there were several open questions that are fundamental to the understanding of shape memory behavior. Shape memory behavior in the nanometer regime had not yet been explored. It was not known whether the transformation microstructures observed in single crystals and large grained materials would persist to nano-sized grains, or whether other transformation microstructures occur at these size scales. The objectives of the research have been to create nanostructured shape memory alloys in bulk and particle form; explore the effect of grain constraint on the nucleation and propagation of phase transformation; investigate scaling effects on shape memory behavior; and improve fatigue life, workability, and superelastic behavior through grain refinement. |

| Composite Materials Containing Shape Memory Alloy Constituents

Prof. Crone is also investigating composite materials with shape memory alloy constituents. Composite materials are critical for many engineering applications because of the resultant properties that arise from the combination of dissimilar constituent materials. The ability to tailor material properties to meet specific high-performance needs makes composite materials very attractive for a wide range of technical applications. Introducing the properties of a shape memory alloy into a composite material creates opportunities for making multifunctional components and components capable of performing in ways that surpass the constituent materials. Some research has been done in this area but the creation of reliable materials is hampered by the disparity in the deformations that can be exhibited by a shape memory alloy compared to matrix materials such as metals and polymers. |

Back to top |